Location

New Road Ashurst

Services

Survey Site

Design

Plant Hire

Transport

Full road construction by Mays Technical Ltd.

Introduction

Mays Technical is established as a leader in the use of innovative excavators and equipment for use in the road construction industry. With a commitment to quality, safety, and innovation, Mays has successfully completed numerous high-profile projects, earning a reputation for excellence and reliability. This case study highlights the company's expertise, project management capabilities, adaptability and successful outcomes in recent projects.

Background

Founded in 2021, Mays Technical Ltd started as a small local contractor and has grown into a major player in the construction sector, as Principal Contractor for District Council Maintenance programmes and appointed a position on Hampshire County Council’s GEN5-1 4 year framework. The company's portfolio includes highways, groundworks, maintenance, haulage and full design and build packages. The services offered encompass project planning, design, execution, and maintenance, ensuring comprehensive solutions for clients.

Problem Statement

Mays was tasked with the development of a crucial highway segment that was notorious for sinkages in the carriageway and deformation of pavement layers under normal traffic conditions, causing pot holes and surface water issues. The goal was to improve the underlying layers of the construction and create a carriageway which could cope with the traffic loading and surface water exposure in the shortest timeframe to minimise disruption to traffic.

Analysis

Project Planning and Design

- We were presented the project with an outline design, budget and start date

- Engaged with stakeholders, including local communities and Local Highway representatives

- Developed a detailed project plan with a focus on sustainability, environmental impact and social value.

Execution

- Employed advanced construction techniques and machinery to expedite the project.

- Implemented a phased construction approach to ensure optimum working hours and minimal disruption.

- Utilized innovative materials for durability and reduced maintenance.

Safety and Quality Control

- Adhered to stringent safety protocols to protect workers and the public.

- Regular quality checks and audits were conducted throughout the project.

- Integrated intelligent traffic management systems to enhance road safety.

Solution

Mays deployed a combination of traditional construction methods and cutting-edge technology to address the challenges. Key elements included:

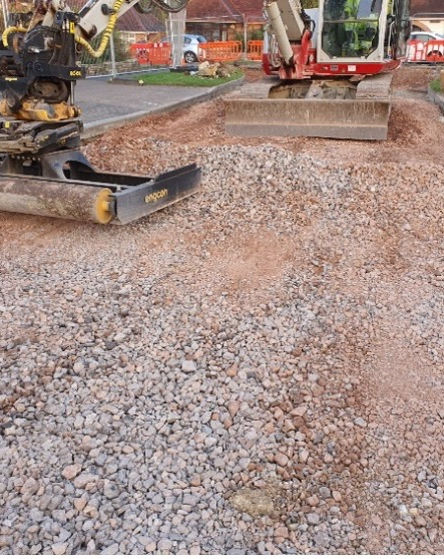

- Excavation of the carriageway to formation level, laid a reinforcing membrane and bed of

Type 1 limestone

- Using our specially adapted 10t excavator and grading beam attachment. The excavator is GPS guided with Engcon tiltrotator which gives it unrivalled mobility with minimum tracked movement of the machine combined with emission reduction system reducing our CO2 footprint. This allowed us to grade the site millimetre level with no increased costs of setting out engineers

- installing an AC20 binder course in two layers, and presenting options to the client for the use of a stress absorbing geo grid which we installed between the layers to strengthen the flexibility of the carriageway

- Installing surface course to tie into the adjusted surface water drainage system.

Results

The project was completed ahead of schedule and within budget, delivering significant benefits:

- Carriageway was profile laid to shape surface water into drainage system.

- Positive feedback from the community and increased satisfaction among stakeholders.

Conclusion

May’s successful execution of this highway project underscores its capability to handle complex road construction challenges efficiently. By combining innovative solutions with a strong commitment to quality and safety, Mays continues to set industry standards and exceed client expectations